Human Robot Collaborations (HRC) is robot that assists humans through an autonomous agent and can be used in workplaces that require high-effort tasks to relieve the muscle load on the worker.

EMG is used in HRC research to determine and optimize the energy-saving effects of the system, inputs for controller methods, and monitor ergonomic positions.

It was found from this study that through the controller method, optimized configurations were achieved that decreased muscle activity and effort during the task as determined by the results of the EMG data.

Human Robot Collaboration (HRC) is the facilitation of physical assistance between humans and robots through an autonomous agent. These systems are used in physically demanding work environments to relieve workload on the human co-worker (the user). HRC’s have been increasingly used in industrial settings where the manufacturing process requires high-effort tasks. EMG in HRC’s can be utilized within the controller to measure intended movement or to optimize the muscular contributions of the user for interaction with the robot. Utilizing EMG in HRC’s increases its’ usability in these high-effort environments.

While HRC’s mitigate the physical stress of the human co-worker, these systems introduce safety concerns. Currently there are strategies to avoid and limit physical contact between the HRC and the co-worker to reduce injuries sustained from the HRC; however, injuries can still be obtained from the pose, tool, or task type while using the HRC. There are methods in place to monitor human ergonomics to reduce the likelihood of injury, but they do not consider the involvement of HRC’s. To include HRC’s, the collaborative robot must have a method that observes and tracks human dynamic and kinematic states. Most researchers turn to off-line modelling, but these models do not address dynamically changing environments. Alternative on-line methods are limited by solely kinematic data or only measuring the hand or arm. EMG has the potential to track these changing human dynamics and input them into computational models.

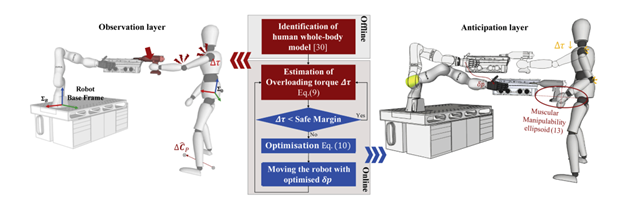

To address the limitations of the current methods, Wansoo Kim and his team, in this study, developed a novel human-robot collaboration control method to allow for more ergonomic working configurations during dexterous tasks. The goal of this control method is to minimize the overall joint torque of the body while constraining either manipulability (velocity and force), joint limits, or any tangible obstacles. This method does this by estimating and monitoring the joint torque force using a dynamic state model in real-time through an Observation Layer. Consequently, an Anticipation Layer predicts the optimal ergonomic configuration that minimizes the overloading joint.

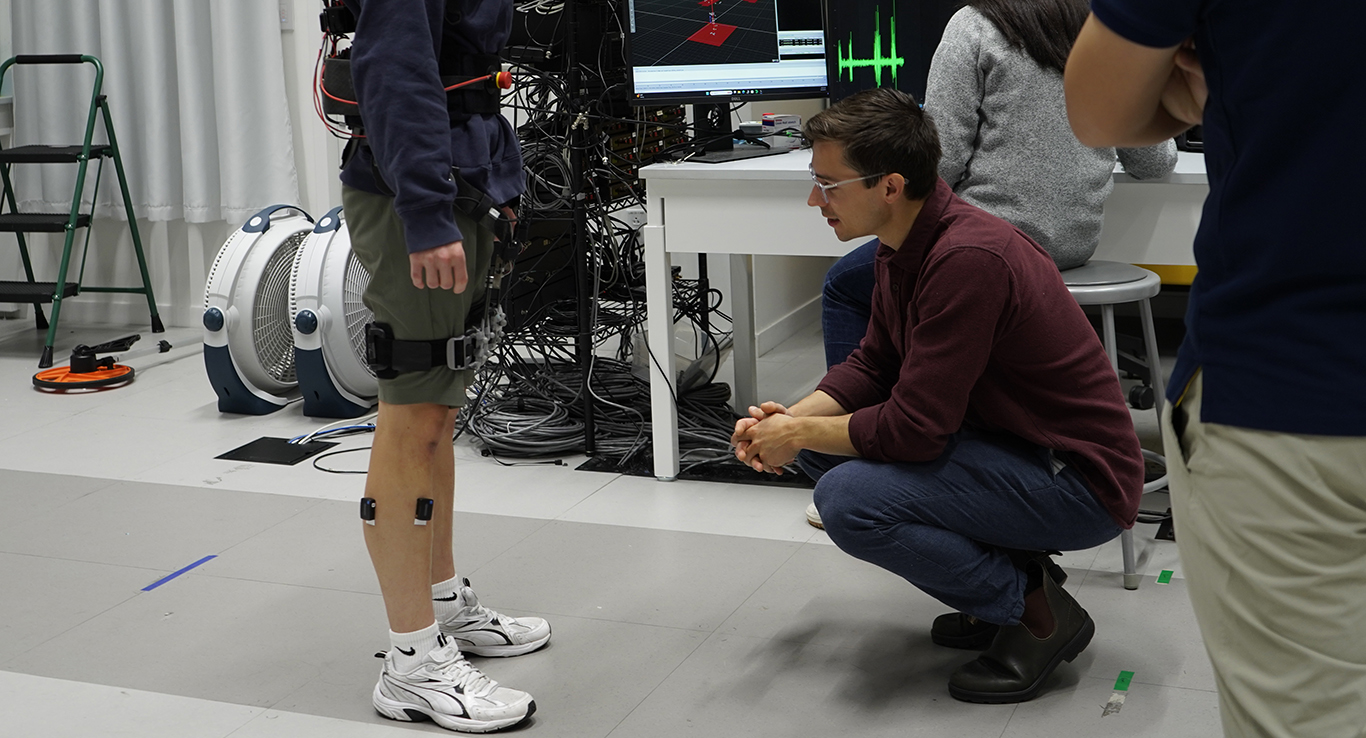

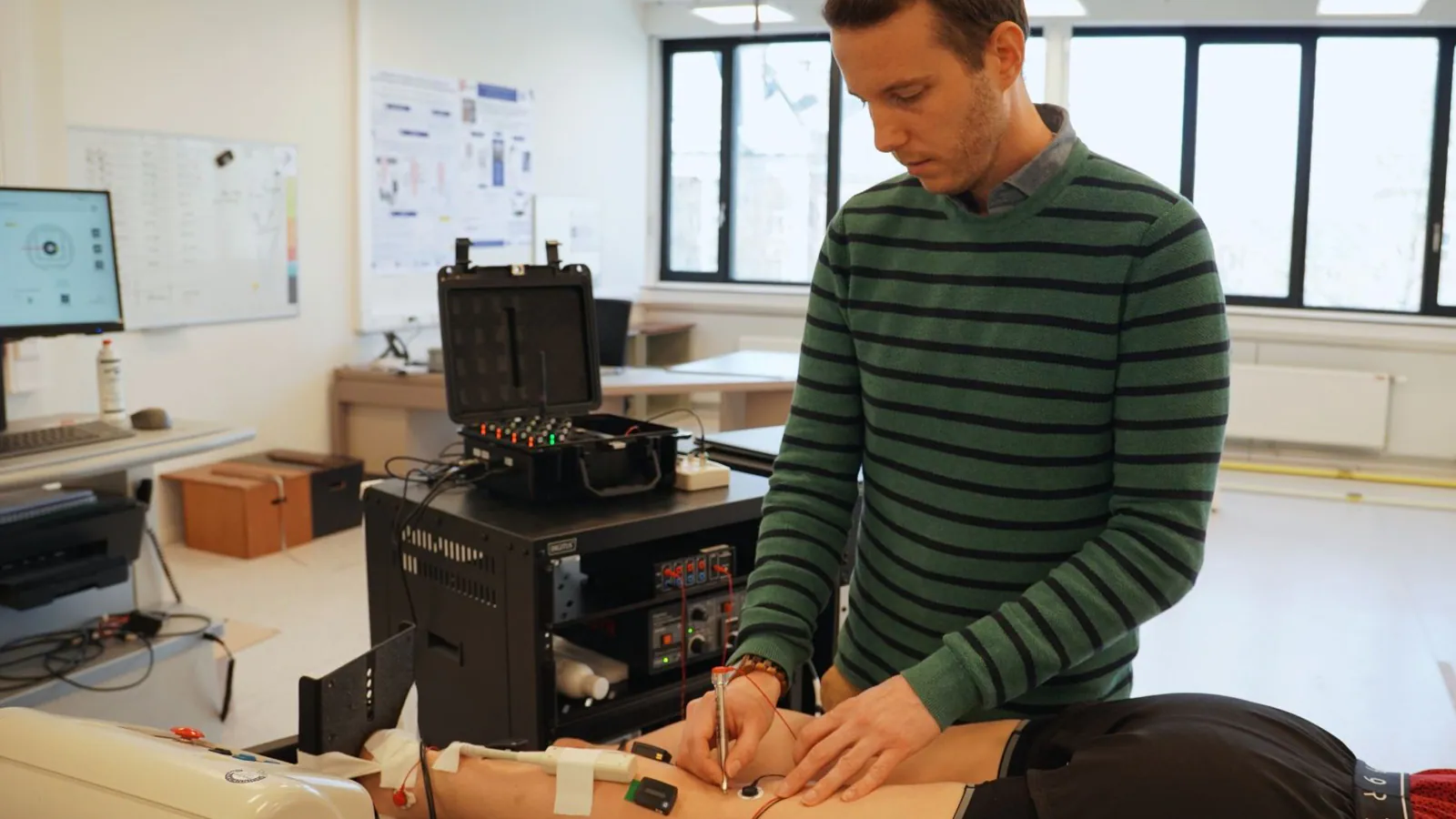

The method was tested based on the optimization of the overloading joint torque, manipulability capacity, and muscle activity measured by EMG. The Delsys Trigno Wireless System was used to verify that the configuration provided by the HRC control method was reducing muscular effort. The EMG sensors were placed on the Anterior Deltoid, Posterior Deltoid, Biceps Brachii and Triceps Brachii. MVC’s were performed to compare the muscle effort during an optimized configuration while completing a task.

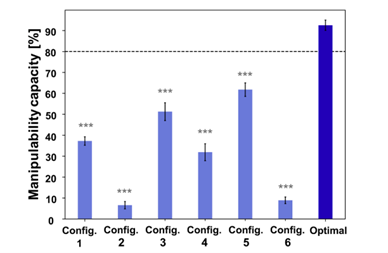

This study revealed that once some of the optimized configurations were achieved, muscle activity and effort decreased during the task as determined by the results of the EMG data. In addition, they found that the HRC brought on a tradeoff between achieving lower body torque and manipulability capacity. For some test configurations according to the control method, as the overall body torque decreased, the manipulability capacity of the arm also decreased. The reduction in manipulability of the arm will restrict the human co-worker’s range of motion and therefore affect task production. However, through the control method, the HRC can configure towards a pose that allows for the most optimal arm manipulability capability and lowest joint force torque to minimize the tradeoff as much as possible.

The purpose of this research was to develop a method that reconfigured a HRC to allow for optimal joint force torque whilst considering other variables. Other methods typically are complex and difficult to implement in an HRC for an industrial working environment. The development of the proposed method simplifies and minimizes the number of instances needed for operation, therefore allowing for easier implementation in an industrial setting. This method was verified for reducing muscle effort through EMG data and provided evidence that the method did give an optimal configuration for the co-worker. The novel control method will expand the knowledge of HRC ergonomics in industrial settings, and the effect it has on workers. From this knowledge, safety procedures can be better tailored to prevent the human co-workers from experiencing injuries.

For more information on how EMG can be used to optimize human-robot collaborations and shared autonomy, reach out to us at contact@delsys.com and explore more about the research area on Delsys Scholar.